In order to protect the common home of mankind, various policies are being implemented around the world to achieve energy saving and emission reduction, and reduce carbon emissions.

The factory is a large building with intensive energy consumption and complex energy consumption. In order to effectively reduce the energy consumption of the factory and reduce energy costs, Acrel has developed a set of factory energy management solutions.

Application

Solution

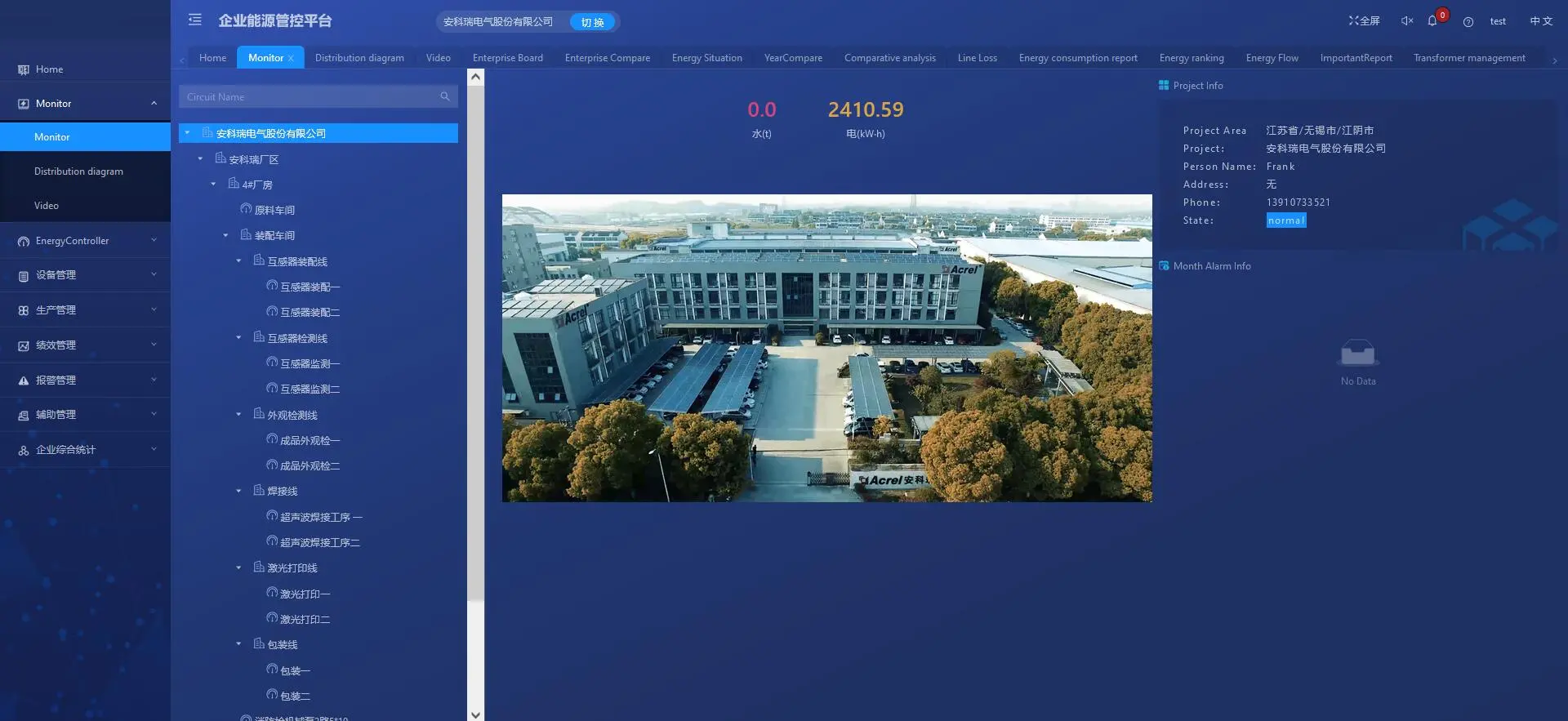

Establish an efficient energy consumption monitoring and management system to conduct real-time monitoring of energy usage and alarms at various points in the factory. So that factory users can monitor the operation of each point in real time, and at the same time grasp the alarms of the points more quickly and efficiently, and provide data support for the factory's technical improvement measures such as peak shaving and valley filling and load adjustment.

Advantage

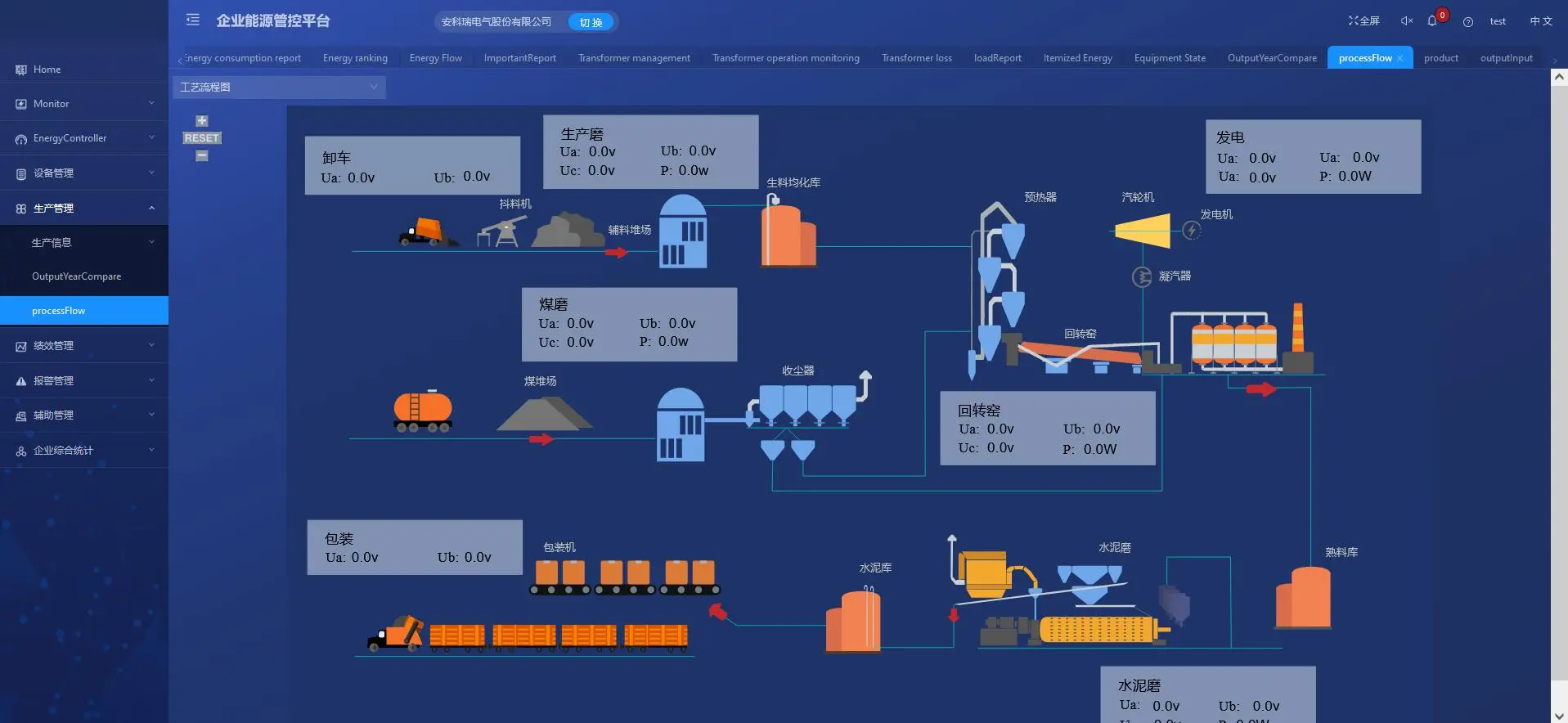

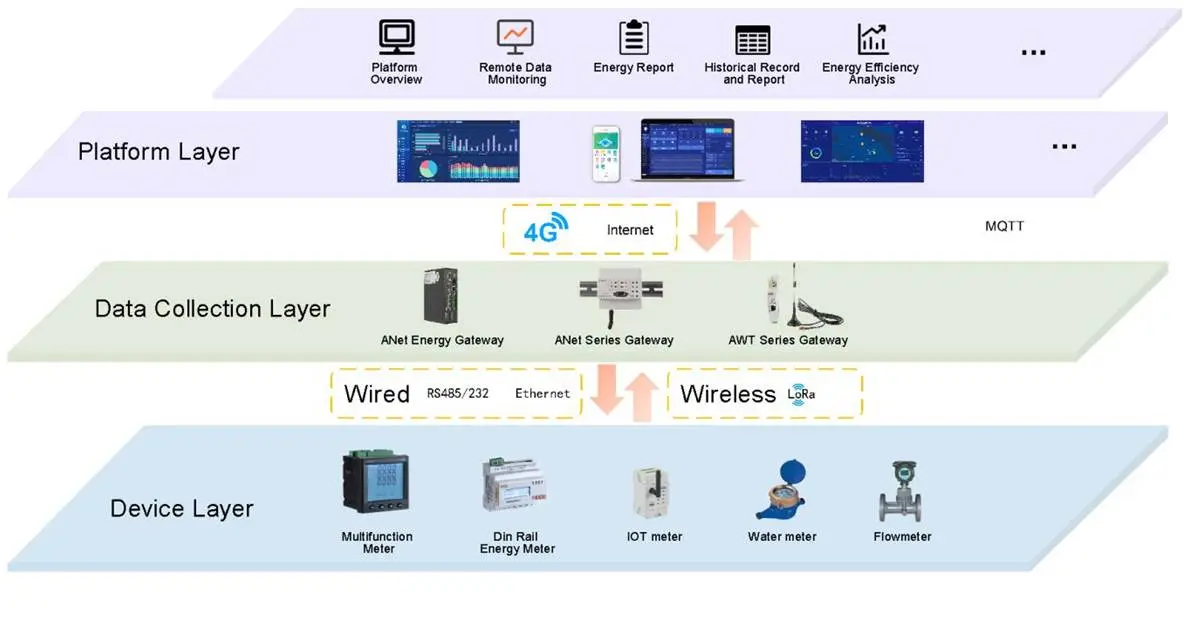

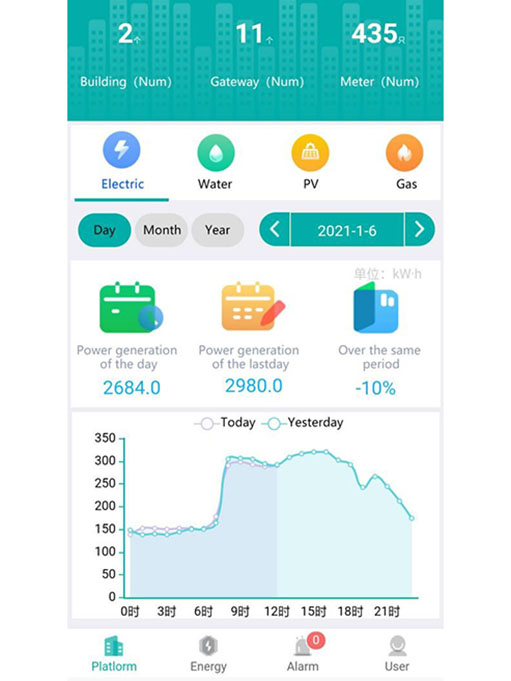

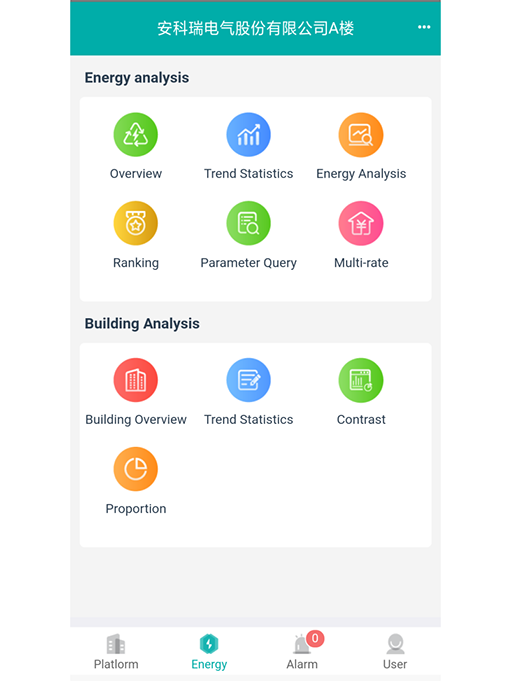

◆ Real-time monitoring of energy: Real-time monitoring of water, electricity, gas and other energy consumption to ensure the safe, continuous and stable operation of energy-consuming links, and display power distribution diagrams, energy flow diagrams, energy balance network diagrams, energy metering network diagrams and other functions.

■ Energy flow diagram: It is necessary to display the consumption of water, electricity and gas in real time on the energy flow diagram; when the energy parameters exceed the limit alarm, it can provide alarm importance level classification, and support APP push alarm reminder, SMS alarm reminder, Email, voice alarm prompt, etc.;

■ Power distribution diagram: Draw the real situation of the power distribution room into the power distribution diagram, and display the real-time water and electricity parameters of the access control, flooding, electricity, water and gas and other instruments connected in real time and the flooding status of the access control.

■ Real-time statistics: Real-time statistics of the energy consumption values of factories, workshops, processes, and equipment for the year, quarter, month, week, day, and shift;

■ Data display: display different energy consumption parameters of different regions and different equipment through real-time curves and historical curves;

◆ Safety detection: Centralized display of energy alarm information, related processing operations on alarm threshold information, online setting of alarm parameters, when energy parameters exceed the limit alarm, alarm importance level classification can be provided, with SMS and APP push , mail, voice and other information alarm prompts.

Plateform

|

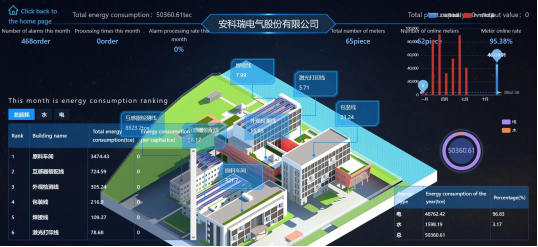

Energy Overview

● Daily Average Load ● Chain Analysis ● Consumption Trend ● Energy Histogram |

Regionalized Monitoring

● Energy Consumption of Procedure ● Energy Report ● Alarm

|

|

Categorical Monitoring

● Sort by Devices ● Energy Trend ● Comparision by days |

Production Line Monitoring

● Energy Consumption of Procedure ● Total Production Output |

3D Diagram

APP

Product Selection

|

Application |

Type |

Functions |

|

|

|

High voltage or Low voltage circuit |

APM810 |

● True RMS Measurements |

|

|

Power cabinet |

AMC96L-E4/KC |

● True RMS Measurements |

|

|

Power cabinet |

ADW400 |

● Measurement: Maximum 4 circuits 3 phase U、I、P、Q、S、PF、kWh、kvarh |

|

|

Power cabinet |

ADL3000-E |

●AC3×220/380V,3×380V,3×57.7/100V,3×100V |

|

|

Power cabinet |

ADL400 |

●AC220V |

|

|

Lighting cabinet |

ADL100-ET |

● AC220V |

|

|

Lighting cabinet |

ADL200 |

●AC220V |

|

|

Lighting cabinet |

ADL10-E |

● AC 220V |

|

|

Gateway |

ANet series |

● Support Modbus-RTU,Modbus-TCP,DLT645, |

Photo on site

Related Products