Factory

Automation Production Line

Quality control

The company regards quality as the lifeline of products, and implements quality checks on the products produced.

The semi-finished products adopt the first inspection, process inspection and completion inspection, and the finished products adopt full inspection, random inspection and regular inspection to ensure product consistency.

The high-precision automatic inspection platform for finished products ensures the reliability of product quality and the timely delivery rate of products.

The introduction of a multi-functional visual inspection platform fills the inspection needs of products with special functions.

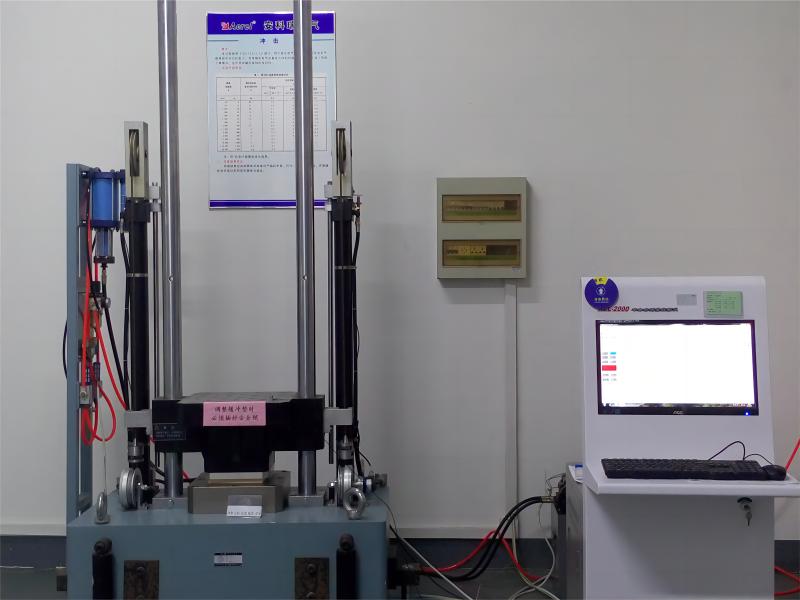

Test Center

Acrel Test Center is affiliated to Acrel Electric Co., Ltd. and was established in 2008. It can conduct various tests such as electromagnetic compatibility, electrical performance, electrical safety, climate environment, mechanical environment, IP protection, HALT/HASS, material testing, etc.

The testing center covers an area of about 1,000 square meters and has more than 40 domestic and foreign test equipment.

It follows the CNAS-CL01/ISO17025 "Testing and Calibration Laboratory Capability Accreditation Guidelines" to establish a scientific and standardized quality management system, and can provide customers with product testing services.

Climate environment test

Climate environment test

Electromagnetic compatibility test

Flame retardant glow wire test

Impact test

IP test

Reliability test

RoHS test

Salt spray test