BA series current transducers use the electromagnetic induction principle,real time measure AC current in grid,adopting the precise constant current technology and the linear temperature technology,change its isolation as standard DC signal output.

BA series current transducers adopts safe power of dc 24V or 12V and has advantages of high overload capacity,high precision and high isolation.It is widely used in industrial automation applications.

Download

Characteristics

|

● Input: 0~(0.1~1)A AC

● Output: 4~20mAV/0~20mA DC

● Power Supply: 12V/24V DC

● Perforation Hole Size: φ50mm

● Applicaiton: Paired with PLC for Industrial Automation

● Accuracy: Class 0.5

● Response Time: ≤350ms

● Installation: 35mm DIN Rail/Screw fixed

● Standard&Certificate: CE

|

BA Series Overview

| Model Name |

Input | Output | Perforation Hole Size(mm) |

|

| AC Current | DC Current | DC Voltage | ||

| BA05-AI/I |

0~(0.5~10)A | 4~20mA/0~20mA | / | φ5 |

| BA05-AI/V |

0~(0.5~10)A | / | 1~5V/0~5V | |

| BA10-AI/I |

0~(8~50)A | 4~20mA/0~20mA | / | φ10 |

| BA10-AI/V |

0~(8~50)A | / | 1~5V/0~5V | |

| BA20-AI/I |

0~(40~200)A | 4~20mA/0~20mA | / | φ20 |

| BA20-AI/V |

0~(40~200)A | / | 1~5V/0~5V | |

| BA50-AI/I |

0~(60~600)A | 4~20mA/0~20mA | / | φ50 |

| BA50-AI/V |

0~(60~600)A | / | 1~5V/0~5V | |

| BA50L-AI/I |

0~(0.1~1)A | 4~20mA/0~20mA | / | |

| BA50L-AI/V |

0~(0.1~1)A | / | 1~5V/0~5V | |

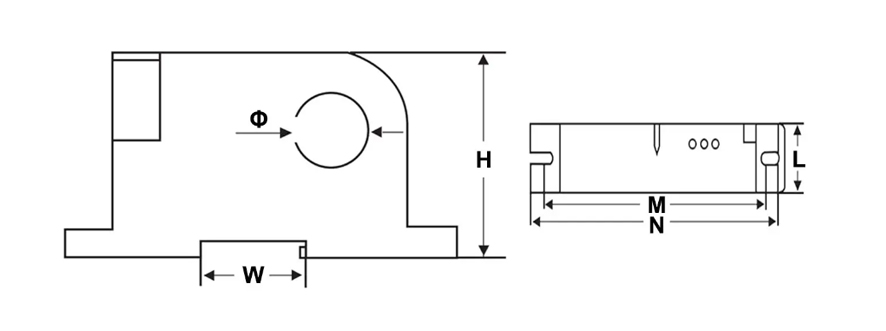

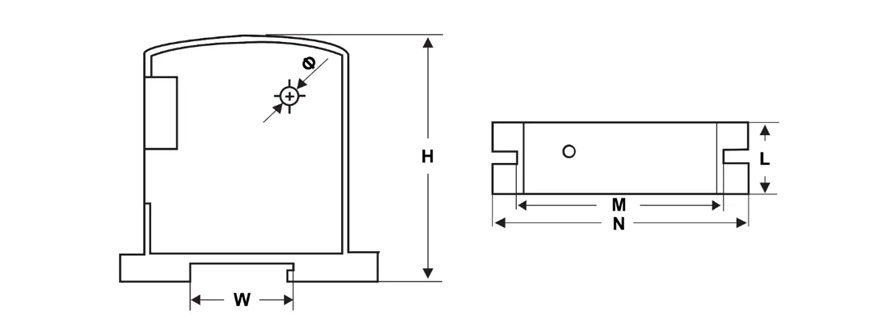

Dimension

| Model Name | Outline Size (mm) | |||||

| W | H | Φ | M | N | L | |

| BA20-AI/I&BA20-AI/V | 35 | 60 | 21 | 93 | 102 | 24 |

| BA50-AI/I&BA50-AI/V | 35 | 84 | 50 | 125 | 135 | 24 |

| BA50L-AI/I&BA50L-AI/V |

35 | 84 | 50 | 125 | 135 | 24 |

| Model Name | Outline Size (mm) | |||||

| W | H | Φ | M | N | L | |

| BA05-AI/I&BA05-AI/V | 35 | 69 | 5 | 62.5 | 76 | 22.5 |

| BA10-AI/I&BA10-AI/V | 35 | 74 | 9.5 | 62.5 | 76 | 22.5 |

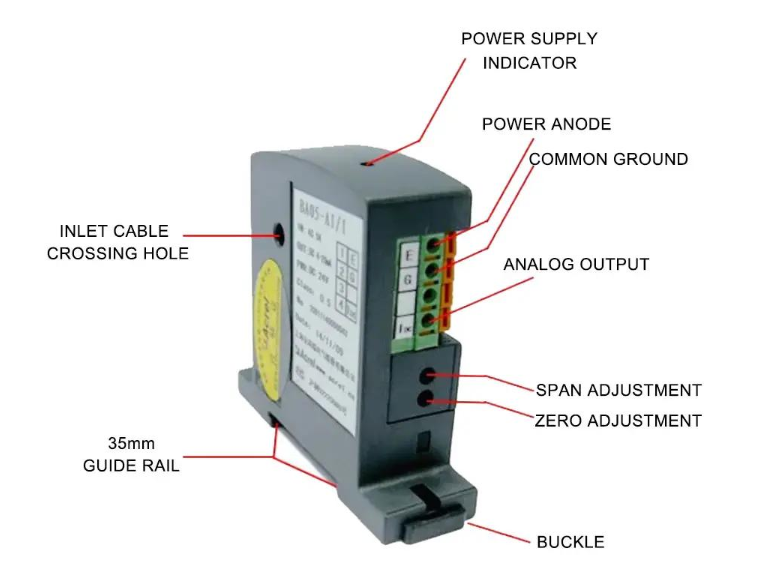

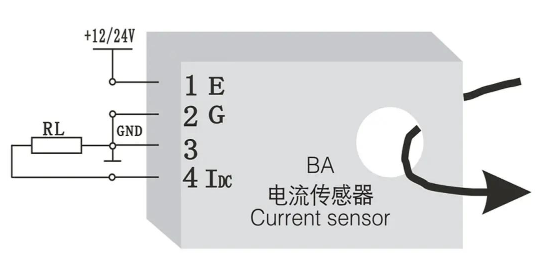

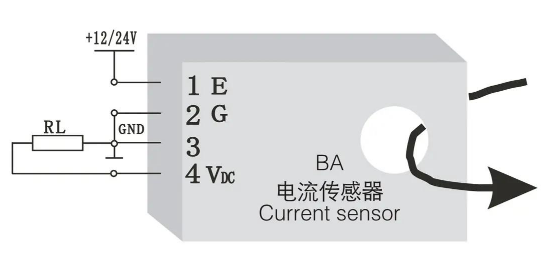

Wiring Terminals Overview

Wiring Terminals Overview of BA Series Current Transducer

Wring

|

|

|

Cable Wiring of BA Series Current Tranducer with DC Current Output |

Cable Wiring of BA Series Current Tranducer with DC Voltage Output

|

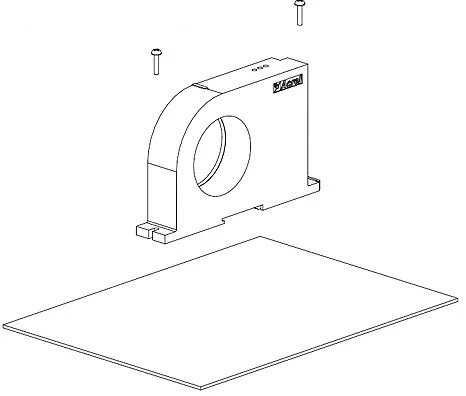

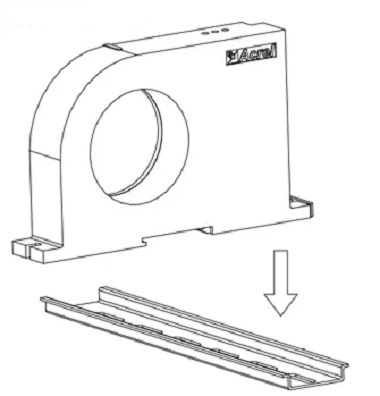

Installation Instruction

|

|

|

Screw fixed installation

On the bottom panel of the cabinet, choose a suitable place to open |

Din Rail installation

Choose a suitable place to install the standard DIN35mm rail,

and install the BA sensor on the rail

|

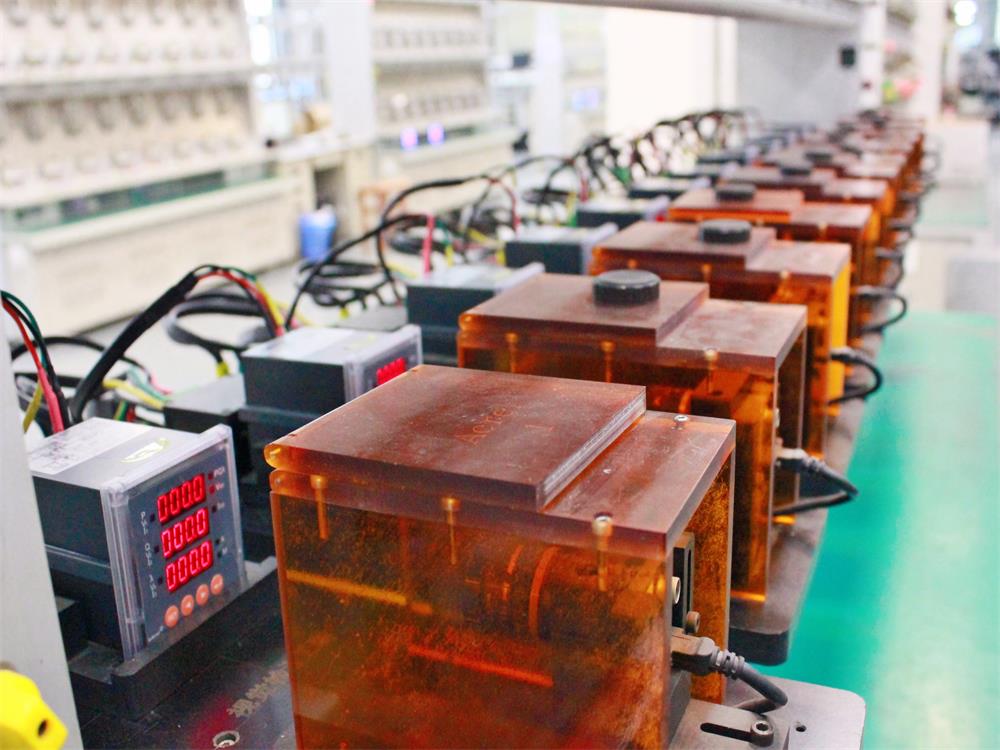

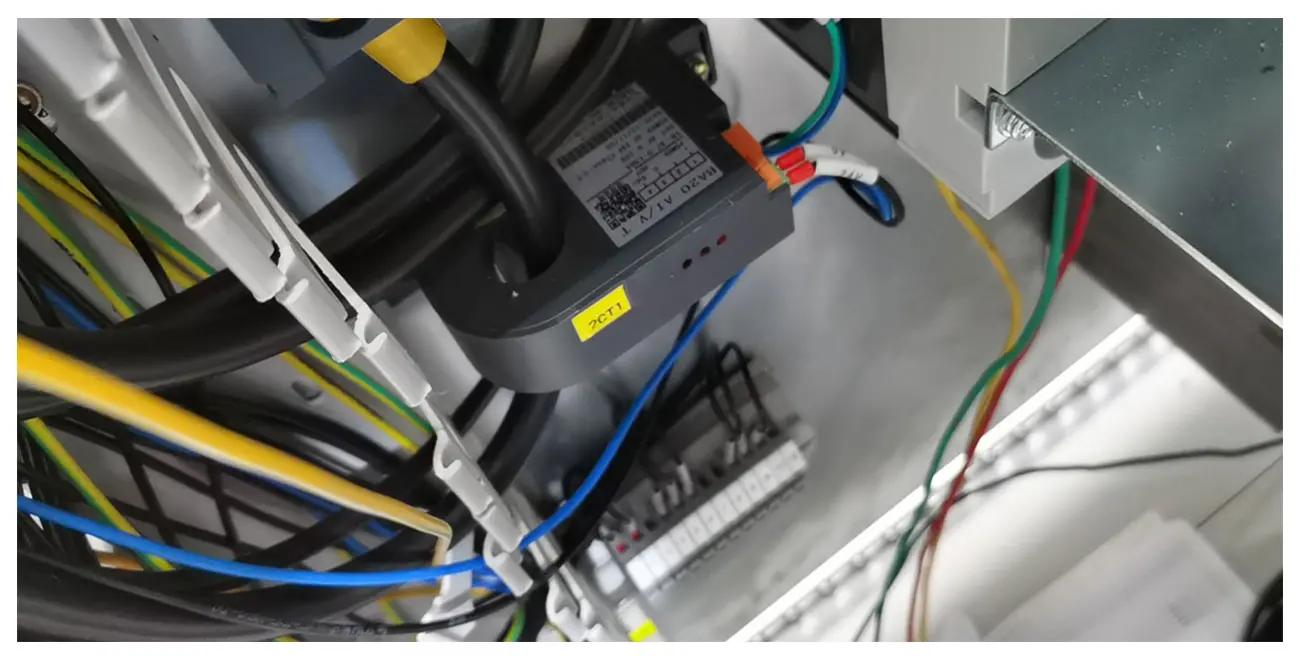

Photo on Site

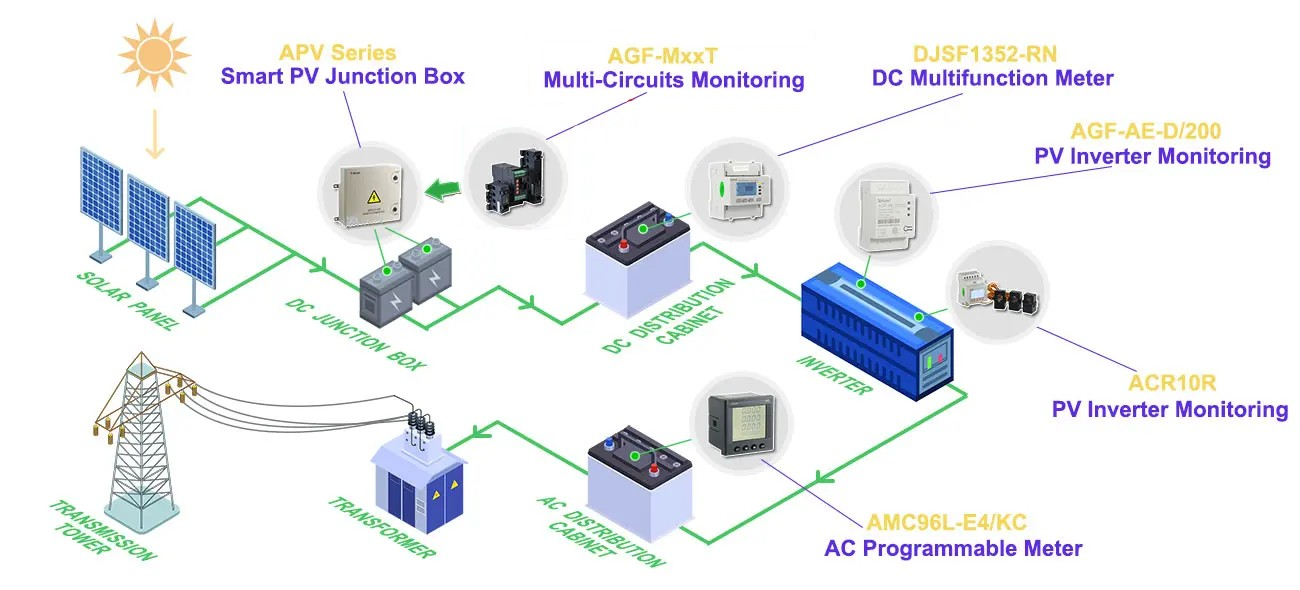

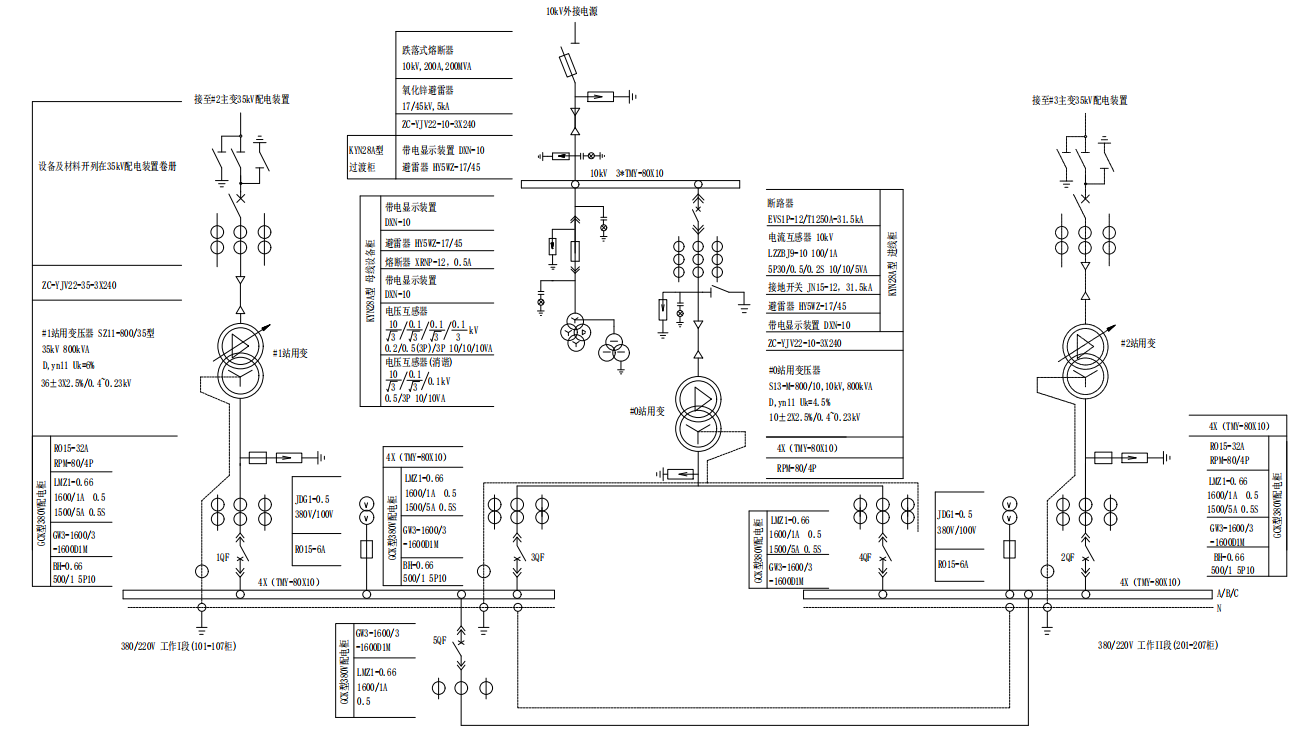

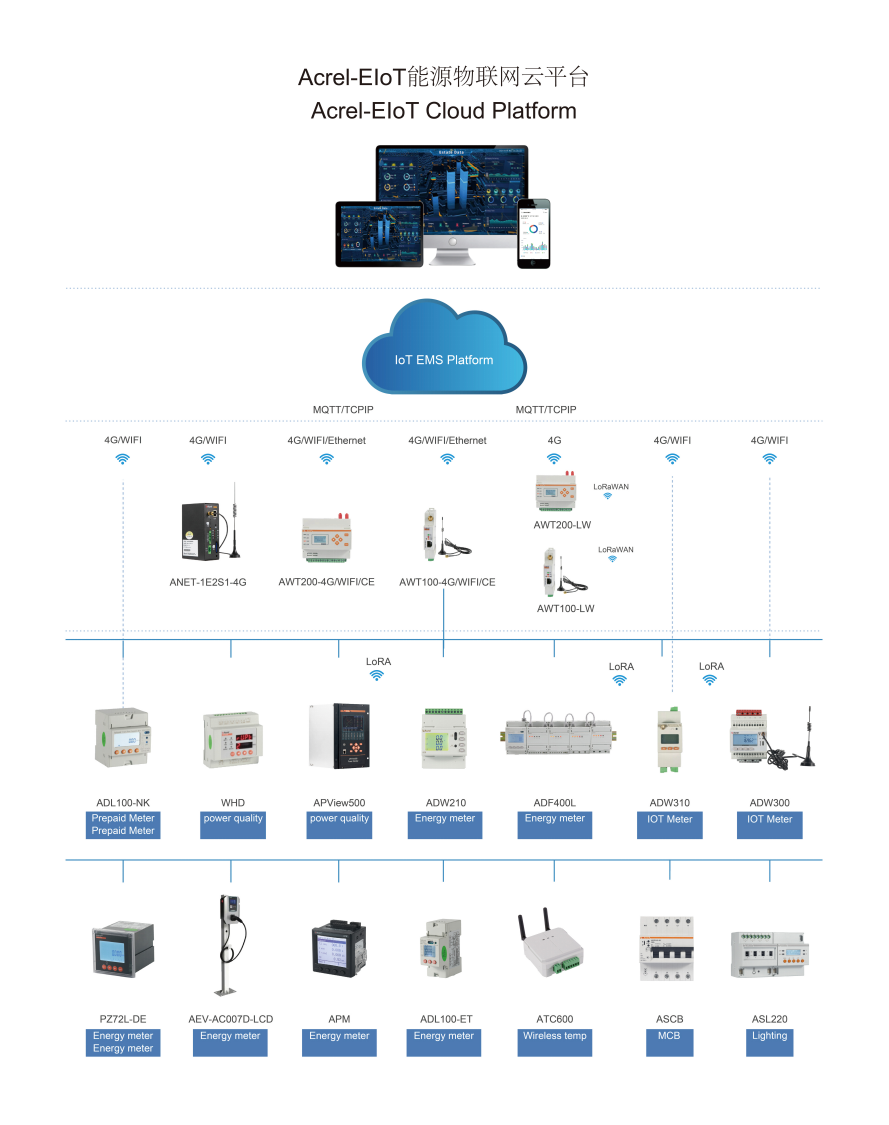

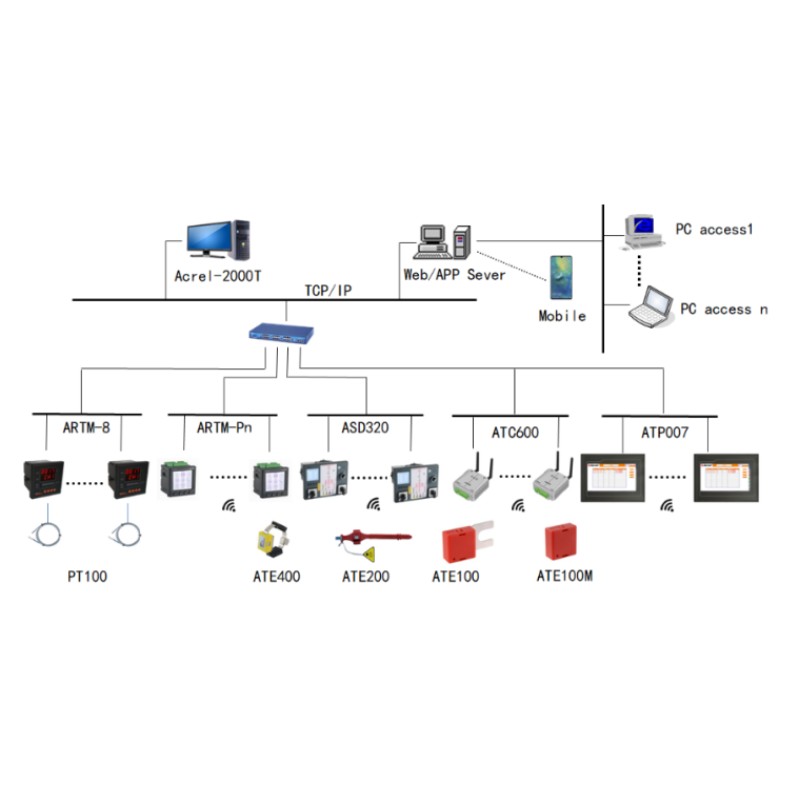

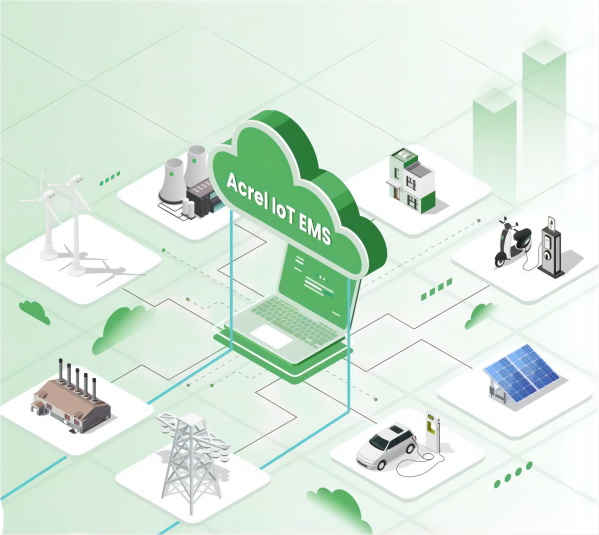

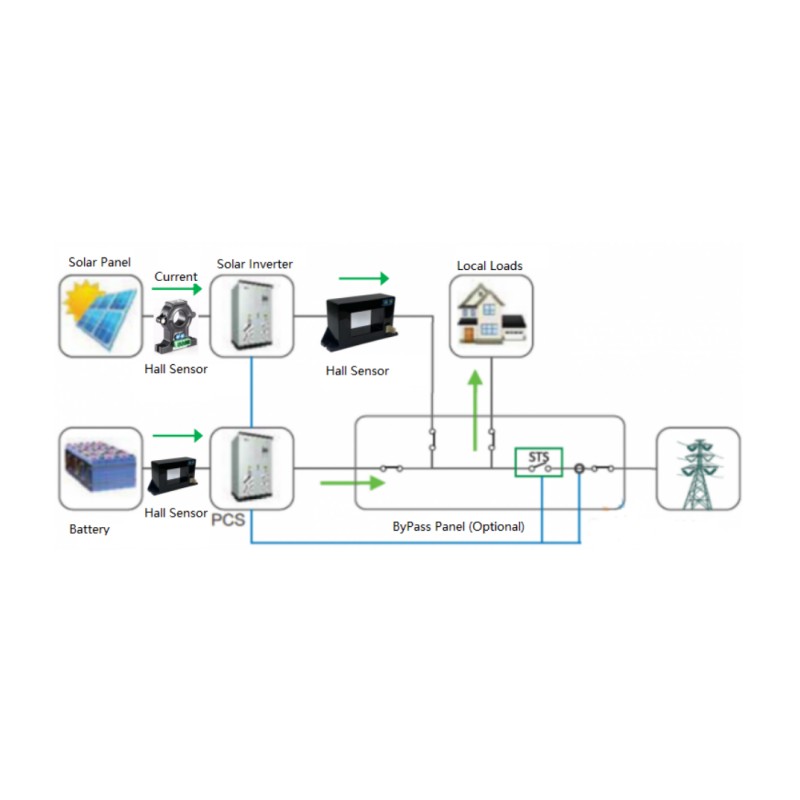

Application

Package

|

MINIMUM PACKAGE

|

|

|

||

|

MINIMUM PACKAGE

|

Package dimensions(1 PC) 16*12.5*7.5cm |

Package Weight(1 PC) 0.23Kg |

||

|

WHOLE BOX PACKAGE

|

Package dimensions(25 PCS) 45.5*26*19.5cm |

Package Weight(25 PCS) 6.75kG |

||

|

PRODUCT HS CODE

|

9030339000 | |||